Laser Center/Edge Finder Holder

So for my next assignment I decided to make a holder for my Laser Center/Edge Finder.

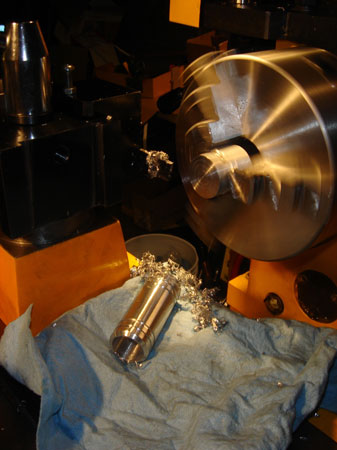

I decided to bore to depth and then clamp the last 1" of stock while using the live center in the hole that I bored. That short would be used for my drawbar mod a couple of days later.

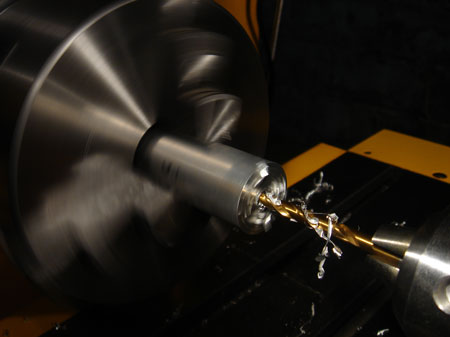

Rockin' the Silver &Deming. I decided to get a little bold here and hit it with the 1/2" bit. I was actually very impressed with the power and stability of the machine. It took this cut and begged for more. Not much more...but more.

I also discovered something interesting here...probably discovered by a few thousand people before me as well. Anyway, I bored out the initial hole and before I hogged it, I shot it full of Tapmatic. Since the oil is viscous it pretty much hangs out inside the bore and acts as a reservoir, constantly lubricating the drill tip.

I have found I can hog almost the entire depth of the bore and keep the drill bit wet, especially if the oil filled bore is over 7/16"

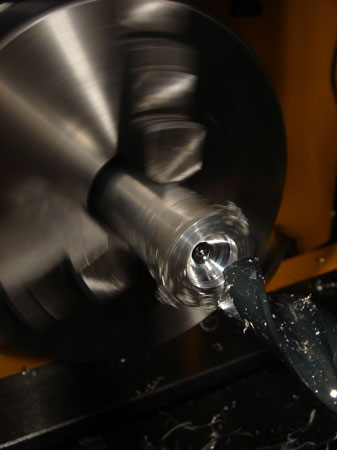

This was my first hog and decent pile of chips. Mmmmmm chips.

Here you can see I've clamped about and inch at the chuck and plugged the live center into the hole I just hogged.

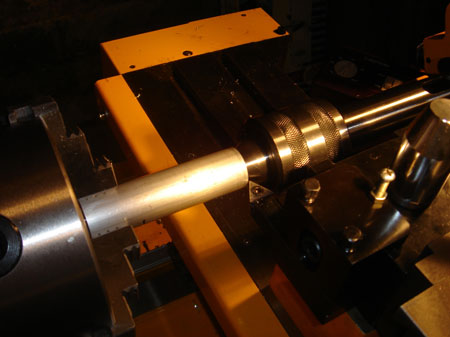

Trying out another tool bit too. I forgot to take pictures after this, but I just took a couple of light cuts on the outside and proceeded to cut some grooves with the parting tool. I also tried out my compound slide for taper cutting and matched the shoulder angle on my LC/EF at the lip of the holder.

Moments after arriving into this world as an LC/EF holder, the chuck is still moving even.

The next little step was to try the "bolt circle" feature on the DRO. I'll have to say there would be no way I could just jump into machining without the DRO. Center up the piece in the vise, enter the hole pattern information and the DRO just tells you where to go. Magic.

I tip my hat to everyone who learned or still does it the old fashioned way.

I drilled out the center so no grit would get trapped in the bottom of the holder and gum up the .0035" hole where the laser comes out of the LC/EF unit. Yes, that is in fact 3.5 thousandths of an inch. That's like, way small.

This is the finished product (on the left). The taper on the holder actually worked out nicely. I put three magnets on the bottom as sort of a tripod, so I can set it anywhere and it will be flat on the surface. On the right is my tool height gauge.