I found some rectangular steel stock in the junk bin. No idea what kind but it machines nicely. It's about 1" x 1/2". I cut a length of about seven inches and trued up the whole bar before I split it in twain on the band saw.

Unfortunately I got a bit over enthusiastic, as usual, and forgot to take very many picutres. Moving on.

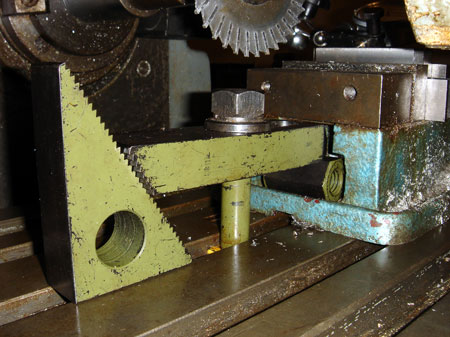

I'd be taking the Cinti 205 for a test drive on this one. Never used a horizontal mill before, but it looks like someone got to this one before I did. A little rough around the edges but she runs smooth.

At this point I already drilled my holes in the bars (the part I forgot to photograph) but there is no big trick. I did clamp both in the vise at the same time so I could be sure the holes matched up exactly. Doesn't make much sense without pictures does it? My fault.

Right now I'm squaring up my work with the dial indicator. Gotta be sure those slots are parallel and perpendicular.

This took quite a bit of fussing. Initially I set up by clamping directly to the table. I was soon obvious that I'd be out of the operating envelope...no more vertical travel in the table. So, I scrounged an ill fitting vise.

As you can see I used a couple hold downs on this side and had to get tricky on the back. Next slide please!

Since the vise didn't line up with the T slots this is how I clamped the back side of the vise. Tricky eh?

Well, it was pretty anti-climactic for me too. One pass, full depth. You can sort of see the drilled holes here too.

This was a bit more exciting. The horizontal mill is pretty cool but I don't expect I'll have one of these at home any time soon. Sure made cutting that 90 degree groove easy though.

This was about three passes and voila.

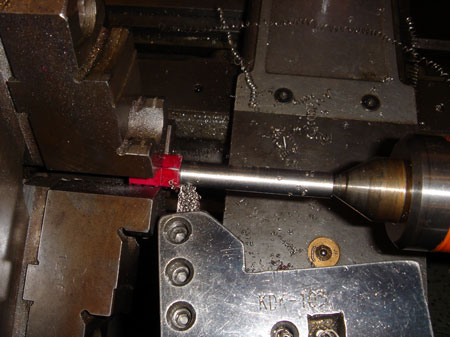

Okay, now it's time to make...the tail of the dog?

Just a piece of steel hex. To the lathe my good man!

Kind of a waste of good hex, but the turning tool I ground worked really well on the steel. I'll flip this and thread the other end.

Ding! Just like a microwave right? All threaded and purdy.

Well, that's it! I've been criticized for my choise of bolts so I'll see if I can find some stainless ones and quell the uprising.

Hey, you ask, what is that extra hole for? Balance I say! Less vibration when that thing is whipping around in circles.

Okay, if you must know I broke off a tap in the first hole. I couldn't get it out and since the two sections are a matched pair I'd have to start over from scratch. So...I just band sawed off the end with the stuck tap and drilled another hole. Balance I say!