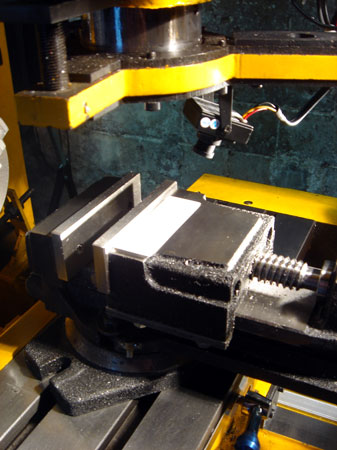

Ah the magic of ebay. I picked up this color camera and LCD screen for a pretty reasonable price. I wanted to use it for two things, first as a closeup magnifier to align my laser. Second, as an extra set of eyes for boring blind holes.

I've been boring some 2" holes to the full depth of the boring tool and it's virtually impossible so see inside the bore once the tool is at a certain depth...except from the back...but I need to be in front to run the machine.

I used a couple of magnets to mount the screen on the mill head. Yeah I know magnets and LCD's might not get along, but I don't see any negative result.

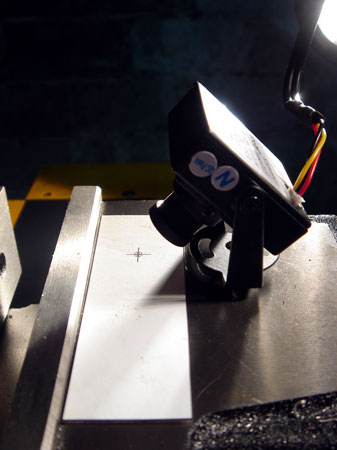

One of my main problems is trying to see the tiny laser dot when aligning my LC/EF. Normally I use a 15X magnifying loupe, which works okay, but it requires a lot of neck strain.

The other thing I find this useful for is locating scribe lines or the center of a round that has been faced on the lathe. My previous method was to take a macro shot using my digital camera and then zooming in on the preview screen. The video camera provides the same result but in much less time.

It's a bit hard to tell from this image and the preceding one, but that laser dot is TINY! This is a target I made up with Adobe Illustrator and the four white segments near the center of the target are so small they're quite difficult to see with the naked eye.

I used the loupe and my digital camera to take this shot. You can even see the fibers on the photo paper. The black lines are very close to the finest that my photo printer is capable of resolving.

It should be noted at this point that I'm aware this method is not a very good one. That is, my laser is about 2 inches from the target...my normal operating distance. I was trying to get better alignment through higher resolution.

However, the result is that if I move the laser further away from the target, any runout is effectively increased. I'm working on a better solution but this is mainly to show the capability of the camera.

Here's the real application. The camera is about 20 inches away from the chuck here. When I'm boring I use a magnet, placed on the head of the mounting screw, to stick the camera right to the tool holder; the same holder I'm actively boring the hole with.

This basically gives you a view about 1" off the axis of the boring tool. I should have taken a photo of that. Why don't I just bore using the DRO? I do, but I still like to be able to see what is going on in there.

I'd really like to be able to mount the camera here, but because the lens is not a macro lens I need to get the camera really close to get enough "magnification."

Please let me know if anyone knows a source of lenses that I could use to retrofit the camera!