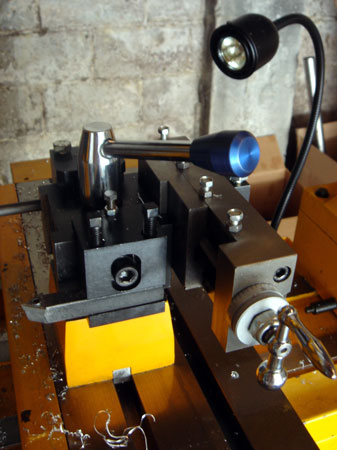

Time to anodize the billet knobs I made. I degreased these with dish detergent and tap water. After drying they took on a slightly yellowish brown cast. I let the knobs soak in the anodizing bath for a few minutes before I turned on the power. I hoped this would provide a light de-smut.

I anodized @ 6ASF for 60 minutes for a.5 mil anodic layer. This is the nickle acetate sealant bath. I found that I had to use 3 of the 300W heaters to really get things hot enough. When it reached boiling I unplugged one heater.

As you can see I'm only using two gallons of liquid, instead of the recommended four. I didn't think there was any point in having way more than I needed and it would take twice as long to heat up.

The knobs have just been rinsed after sealing. For the dye step I'm actually only using a one gallon bath. I placed a two gallon bucket inside my six gallon and this works great. One gallon is much easier to heat and the environment inside the larger bucket helps keep things insulated.

I had a tough time getting a good connection with the threads inside the knobs. I tried a bunch of different things but I found one solution that seemed better than the others.

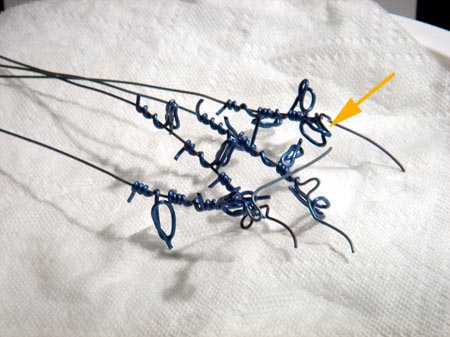

The orange arrow shows a good bend in the wire. Basically you just take about 1 inch and bend it back on itself 180 degrees. Grab that 1 inch loop and bend it back on itself again. You end up with something that can be expanded in two directions instead of just one (like a single loop).

Well, that's it. I'll take some more pics once I get them back on the machine.