Simple hanging setup. I anchored the aluminum wire in the threaded holes and then wraped that around the titanium hanger wire.

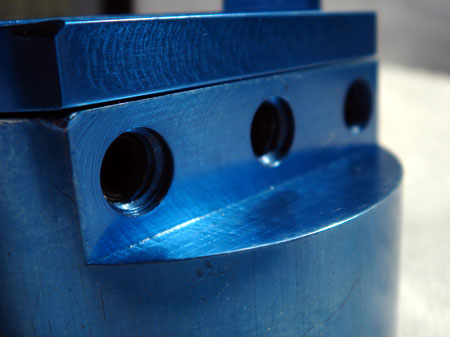

If I did this again I'd rotate the body of the ball turner during the anodizing process. It seemed like the coverage was not that even.

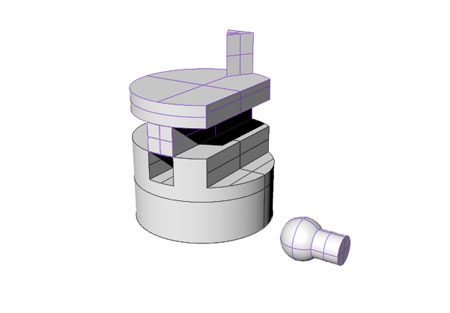

I made a quick model in Rhino and a couple of clicks gives me the surface area for all the parts. Nifty.

I must have miscalculated something, because the color density appears much lower on this run. I was shooting for .25 mil since the fit is quite close where the two halves slide together. I seems like I might have come out with even less than that.

You can see the dented corners where I dropped the thing on the floor. So it goes. The inside of the threaded holes anodized quite well which was a bit surprising since they did not face the cathodes at all.

I used a 3D model I built in Rhino to get the surface area for the part. Then I just plugged it into the online 720 Rule calculator and presto.